REQUEST A QUOTE

Every time you contact ZAVA you can depend on

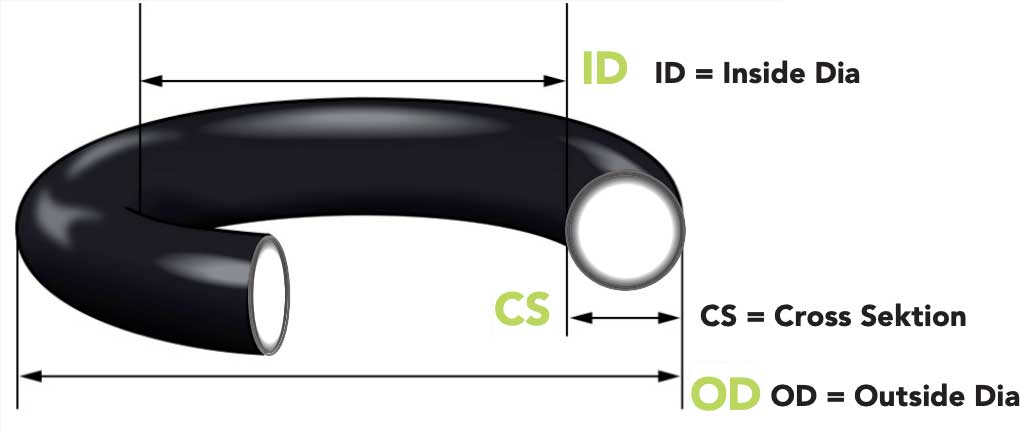

How to measure an O-Ring

O-rings are round mechanical seals that keep gas or liquid from passing through an opening. Over time, these seals may wear out and require replacement. If you’re planning to replace an O- ring, a good fit is critical.

Place the O-ring on a clean, flat, level surface. Determine the inside diameter. Use a ruler to measure from one inner edge to another.

To measure the outside diameter, use a ruler to measure from one outer corner of the O-ring to the other outer corner.

Measure cross section. Place the O-ring into a vernier calliper. Lightly clamp the jaws of the calliper onto the O- ring, but do not compress it. Record the thickness of the ring (the cross section).

If you only have two of the O-ring diameters then you can determine the third diameter with the following equations: Measurements: Outside Diameter (OD) = Inside Diameter + (2 x Cross Section). Inside Diameter (ID) = OD – (2 x CS). Cross Section (CS) = OD – ID, ÷ 2.

Converting Length to Inside Diameter:

(Length ÷ 3.142) – Cross Section = Inside Diameter